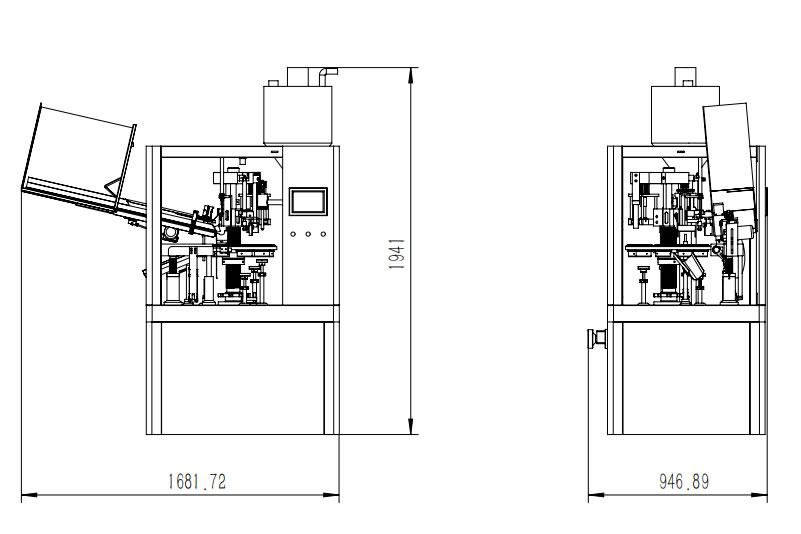

HX-009H Fully Automatic Tube Filling and Heat Sealing Machine

Consult now to get discount

- High quality

- Fast delivery

- After-sales guarantee

Meet the HX-009H: Your Ultimate Solution for Tube Filling and Heat Sealing

Advanced Features of the HX-009H Fully Automatic Tube Filling and Heat Sealing Machine

- The mechanical transmission part is closed below the platform, which is safe, reliable and pollution-free;

- The filling and sealing part is installed above the platform, and the semi-closed non-static outer frame is visible in the cover, which is easy to observe, operate and maintain;

- Stainless steel operation panel, plexiglass protective cover and door protection function installed;

- Slant-hanging tube warehouse, which can accommodate more tubes,

- The upper tube device is equipped with a vacuum adsorption device. After the upper tube interacts with the pressure tube device, the tube is inserted into the upper tube station;

- Photoelectric benchmarking station, using high-precision probes, stepping motors, etc. to control the tube pattern to be in the correct position;

- No tube, no filling, when the injection is finished, the air blowing device blows off the paste tail; anti-drawing, anti-drip filling

- The heating temperature of the end sealing adopts (Leister hot air gun) internal heating at the end of the tube, and the external cooling device is equipped;

- At the same time of sealing the end, the production batch number or date is automatically embossed on the position required by the process;

- Waste cutting manipulator cuts the waste edge at the tail of the tube, and seals with special shapes such as right angle, R angle or arc;

- Failsafe alarm, overload shutdown, water pressure protection, air pressure protection.

Specification & Technical parameter

| Production capacity | 40 pieces/min |

| Filling capacity | 5-250ml |

| Hose diameter | 15-50mm |

| Hose length | 50-220mm |

| Filling error | ≤±1%; |

| Motor power | main motor 1.1kw heat sealing power 3kw |

| Working pressure | 0.60MPa |

| Air consumption | not less than 600L/min |

| Equipment weight | 750kg |

| Dimensions | 1700*1000*2000mm |

| ITEMS | BRAND | ORIGIN |

|---|---|---|

| PLC | DELTA | TAIWAN |

| Frequency Changer | DELTA | TAIWAN |

| Touch Screen | EVIEW | TAIWAN |

| Encoder | Omron | JAPAN |

| Hot Air Generator | Leiste | Switzerland |

| Thermometer MODE | DELTA | TAIWA |

| Proximity switch | SICK | GERMANY |

| Color Code Sensor | PANASONIC | JAPAN |

| Air Pressure Control System | Omron | JAPA |

| Change Speed Motor | WANNAN | CHINA |

| Main Pneumatic component | AIRTAC | TAIWAN |

| Air-break switch | CHNT | CHINA |

| Emergency Swift | Schneider | FRANCE |

| Power switch | Schneider | FRANCE |

| Power lock | Schneider | FRANCE |

| Power indicator | Schneider | FRANCE |

| Ac contactor | Schneider | FRANCE |

| Material Level Sensor (optional) | P+F | Germany |

| Material contact parts | 316L Stainless Steel | CHINA |

| Machine Structure | 304 Stainless steel | CHINA |

Reviews

There are no reviews yet.