X15-2XY Matrix Dual-Head Microdose Filling Machine

Consult now to get discount

- High quality

- Fast delivery

- After-sales guarantee

Meet the X15-2XY: Your Ultimate Solution for Matrix Dual-Head Microdose Filling Machine

The X15-2XY Matrix Dual-Head Micro-Dose Filling Machine features a SUS304 stainless steel casing, offering an aesthetically pleasing and well-engineered design. The filling pump is made of ceramic material, ensuring precision, wear resistance, and resistance to acids and alkalis. The machine is equipped with an industrial-grade controller and a color touch screen, forming a reliable control system for stable and dependable operation. This equipment is easy to operate and delivers consistent performance, making it the preferred choice for precision quantitative filling in industries such as food, pharmaceuticals, chemicals, cosmetics, and more.

Advanced Features of the X15-2XY Matrix Dual-Head Microdose Filling Machine

- High Precision Filling: The ceramic filling pump ensures exceptional accuracy and wear resistance, making it ideal for applications requiring precise dosing.

- Durable and Resistant: The SUS304 stainless steel casing and acid-alkali-resistant materials provide long-lasting durability, even in harsh environments.

- User-Friendly Operation: Equipped with an industrial-grade controller and color touch screen, the machine offers easy operation and reliable control, ensuring stable and consistent performance.

Compact Machine

Small Footprint

Easy to Maintain

PLC Touch Screen

Function Switch

Control Nozzles Separately

Output Count

Parameter Adjustment

Set the Times of Filling

Set the Movement Speed of Nozzles

Warnning Check

Check the Warnning Information

Locate Problem Quickly…

Technical Parameters

| Mode | X15-2XY |

| power | AC220V 50/60HZ 650W |

| Material | Plunger, pump housing (99.99% alumina) |

| Filling accuracy | ±≤0.5% |

| Rotate Speed | 0-200RPM |

| Placement Angle | 20 degrees |

| Throughput pressure | 0.5MPa |

| Maximum suction height | 4mm |

| Maximum output | 870ml/min |

| Output quantity per revolution | 2.9ml/rev single head |

| Filling times per minute | 0-50times/min |

| Weight | 110kgs |

| Dimensions | L810 * W400 * H800mm |

| Mode | X05 | X07 | X10 | X13 | X15 | X22 | X25 | X36 |

| Plunger diameter | 5mm | 7mm | 10mm | 13mm | 15mm | 22mm | 25mm | 36mm |

| Material | Plunger, pump housing (99.99% alumina) | |||||||

| Output quantity per revolution | 0.17ml/rev | 0.3ml/rev | 0.7ml/rev | 1.6ml/rev | 2.9ml/rev | 6ml/rev | 12ml/rev | 25ml/rev |

| Filling accuracy | ±≤1% | ±≤0.5% | ±≤0.5% | ±≤0.5% | ||||

| Rotate Speed | 0-600PRM | 0-500PRM | 0-300PRM | 0-150PRM | ||||

| Placement Angle | 15° | 20° | 20° | 20° | ||||

| Throughput pressure | 0.6MPa | 0.6MPa | 0.5MPa | 0.4MPa | ||||

| Maximum suction height | 4mm | |||||||

| Weight | 1kgs | 2kgs | 3.5kgs | 7.5kgs | ||||

Ideal Applications for the X15-2XY Matrix Dual-Head Microdose Filling Machine

- Suitable for use in universities, research institutions, pharmaceutical factories, cosmetic factories, hospitals, and other facilities.

- Applied for precision quantitative filling in industries such as food, pharmaceuticals, medicine, chemicals, and cosmetics.

- Ideal for precision quantitative filling of liquids like biological reagents, oral liquids, injection solutions, cosmetics, and fragrances.

- Capable of precision quantitative filling for various acidic and alkaline liquids.

Products gallery

- Precision Ceramic Piston Pump

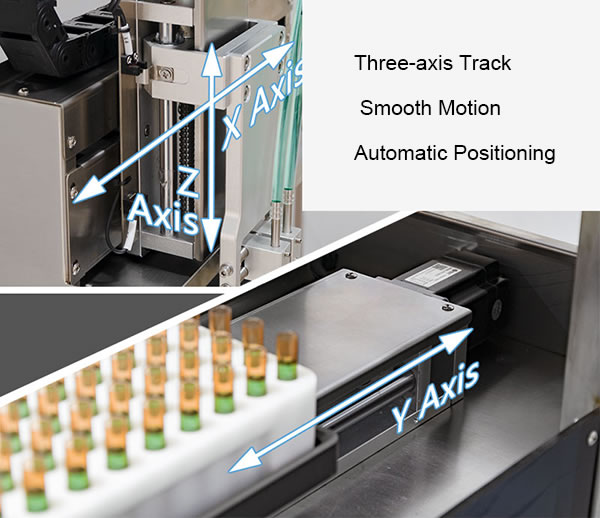

- X, Y, Z Axis

Reviews

There are no reviews yet.