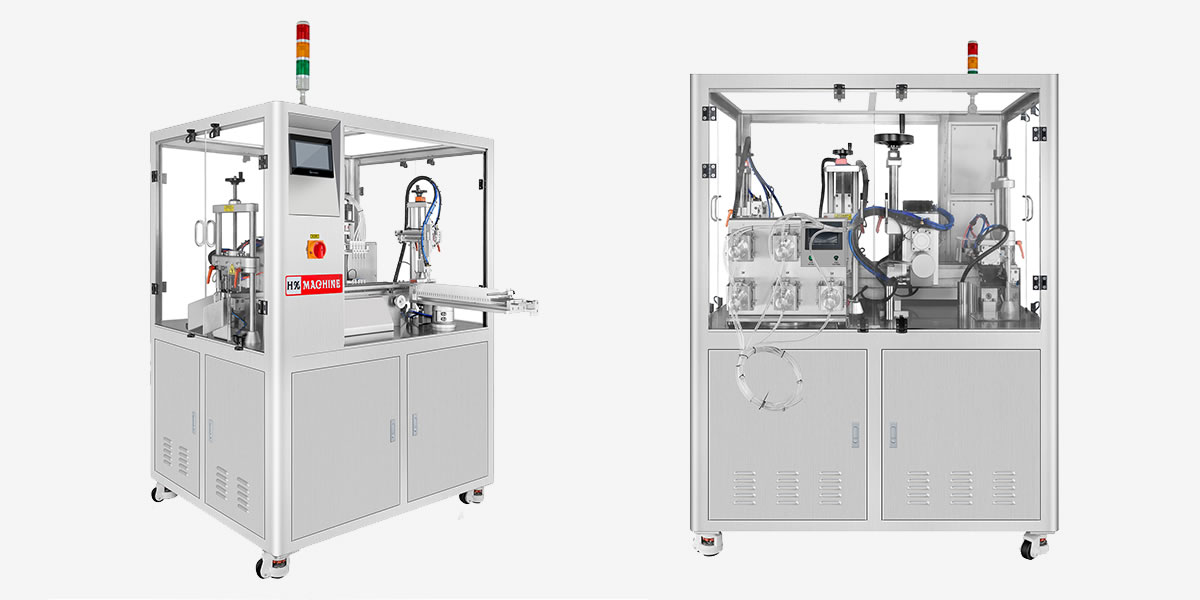

HX-005H Fully Automatic Monodose Strip Tube Filling and Sealing Machine

Consult now to get discount

- High quality

- Fast delivery

- After-sales guarantee

Meet the HX-005H: Your Ultimate Solution for Monodose Strip Tube Filling and Sealing

Advanced Features of the HX-005H Fully Automatic Monodose Strip Tube Filling and Sealing Machine

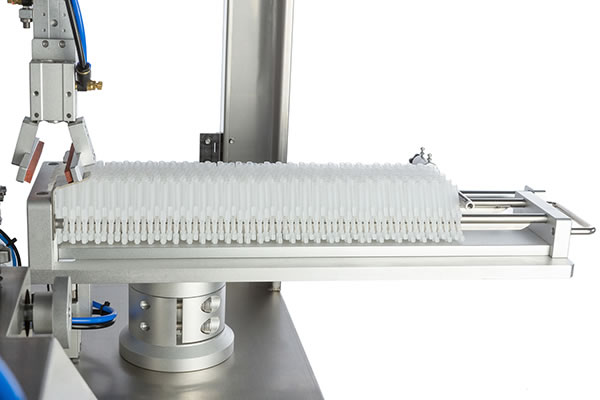

- Machine is specially designed for 5 in 1 tubes, suitable for mass production of 5 in 1 tubes.

- Manually tube feeding, automatic filling, sealing, end trimming.

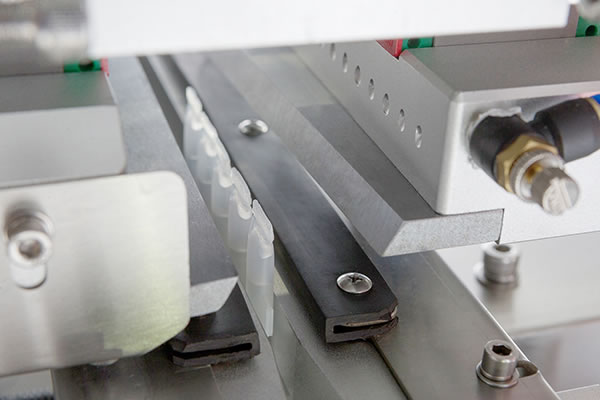

- Adopts ultrasonic sealing technology, no need warm up time, more stable and neat sealing, no distortion and low reject rate less than 1%.

- Independent R & D for digital ultrasonic automatic tracking electrical control box, no need manual adjust the frequency, with power auto compensation function, avoiding the reduction of power after long time use. Could freely adjust the power based on tube material and size, stable and minimum the fault rate, extend the life span than the normal electrical box.

- PLC with touch screen control system, providing friendly operation experience.

- Made of 304 stainless Steel, acid and alkali resistance, corrosion resistance.

- Standard equipped with peristaltic pump filling system, high accuracy filling, and suitable for liquid filling.

- No tube, no fill, no tube, no seal function, reducing the machine and mould loss.

- Cam indexing system could position precisely for six working stations.

- Titanium alloy screw is used for the connection between the mold and the transducer of this machine.

- The machine is equipped with C440 stainless steel material cutter.

Ideal Applications for the HX-005H Fully Automatic Monodose Strip Tube Filling and Sealing Machine

Widely used for food, pharmaceutical, cosmetics and chemical 5 in 1 tube filling and sealing.

- 3 ml

- 0.8 ml

- 1 ml

- 1.5 ml

- 1.5 ml

- 2 ml

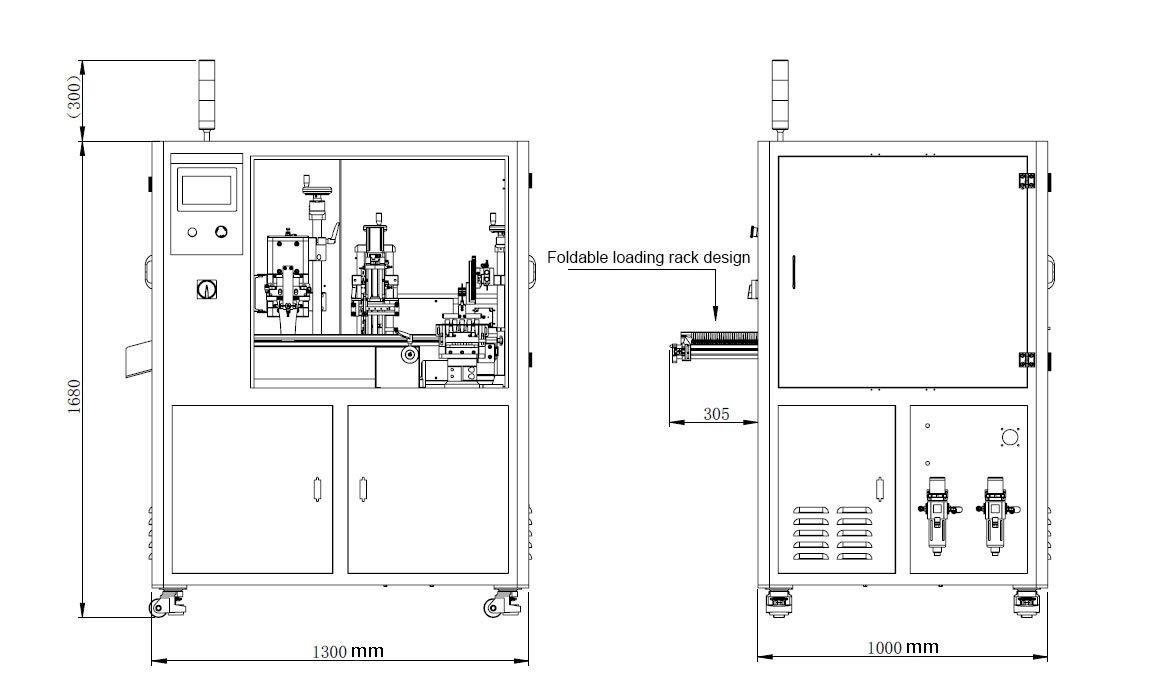

Specification & Technical parameter

| Machine Parameters | |

| Model | HX-005H |

| Frequency | 20kHz |

| Power | 2600W |

| Power supply | AC220V/110V |

| Filling Range | 0.3-10ml Rotary Valve Plunger Pump 1-10ml Valveless Plunger Pump |

| Filling accuracy | ±0.05g |

| Capacity | 15-20pcs/min |

| Tube diameter | 1-7dose/50-135mm |

| Tube height | 50-150mm |

| Working pressure | 0.6 MPa |

| Size | L1300*W1300*H1950mm |

| N.W/G.W | 514kgs |

| Main part list: | |

| Ultrasonic system | Digital auto frequency Tracking |

| Main Machine PLC | Mitsubishi, Japan |

| electric relay | Omron, Japan |

| Touch Panel | WEINVIEW, China Taiwan |

| Photoelectric switch | Omron, Japan |

| Air cylinder | AirTAC, China Taiwan |

| Solenoid valve | AirTAC, China Taiwan |

| Transducer | CN |

| Air source processor | Coolmay, CN |

| Servo Motor and driver | AirTAC, China Taiwan |

| Ceramic pumps HMI and PLC | Coolmay, CN |

| Stepping motor and driver | Leadshine, CN |

Reviews

There are no reviews yet.