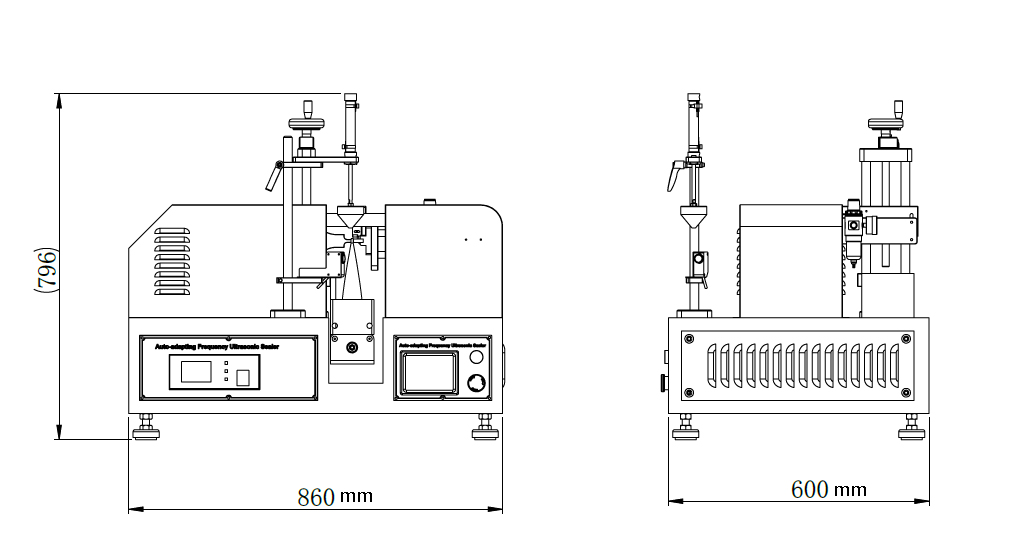

HX-007 Semi-Automatic Ultrasonic Plastic Tube Sealing Machine

Consult now to get discount

- High quality

- Fast delivery

- After-sales guarantee

Meet the HX-007: Your Ultimate Solution for Plastic Tube Sealing

HX-007 Semi-Automatic Ultrasonic Plastic Tube Sealing Machine is a high-quality and high-performance hose sealing and packaging machine. It adopts manual tube loading, automatic color mark detection, automatic tail sealing, and automatic tail cutting. It adopts PLC control and touch HMI.

The operation of this equipment is simple, stable and reliable, which can help enterprises improve production efficiency and reduce labor intensity. It is the first choice for improving packaging grades.

Advanced Features of the HX-007 Semi-Automatic Ultrasonic Plastic Tube Sealing Machine

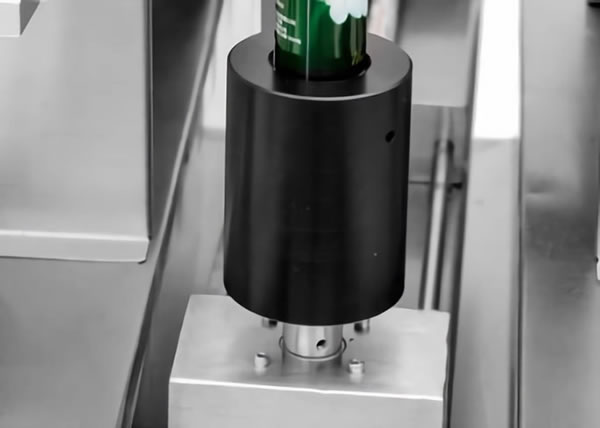

- Adopts ultrasonic sealing technology, no need warm up time, more stable and neat sealing, no distortion and low reject rate less than 1%.

- Manually feed the tube, press start button, machine could automatically identify the registration mark, sealing (with coding), end trimming.

- Independent R &D for digital ultrasonic automatic tracking electrical control box, no need manual adjust the frequency, with power auto compensation function, avoiding the reduction of power after long time use. Could freely adjust the power based on tube material and size, stable and minimum the fault rate, extend the life span than the normal electrical box.

- PLC with touch screen control system, providing friendly operation experience.

- Made of 304 stainless Steel, acid and alkali resistance, corrosion resistance.

- “Panasonic” high sensitive sensor with stepping motor, could track the registration mark precisely.

- Table top design, practical and compact.

Safety Acrylic Cover

Protection cover, safety and beautiful design, anti-clamping hand

Safety Acrylic Cover

Protection cover, safety and beautiful design, anti-clamping hand

Add the Positioning device at color mark tracking station

More stable in color mark tracking Minimum the tube deformation influence to the accuracy

Adjustable lifting Bracket

Could adjust according to different tube height, digital position indicator, visual in adjustment

- Tube Holders

- Date Code

Technical Parameters

| Model | HX-007 |

| Frequency | 20kHz |

| Power | 2600W |

| Power supply | AC220V/110V |

| Filling Range | / |

| Filling accuracy | / |

| Capacity | 10-15pcs/min |

| Tube diameter | 13-50mm |

| Tube height | 50-210mm |

| Working pressure | 0.5 MPa |

| Size | L850mm*W600mm*H730mm |

| N.W/G.W | 75kgs |

Main part list

| Ultrasonic system | Automatic frequency tracing |

| Benchmarking electric eye | Panasonic, Japan |

| PLC screen | Coolmay,CN |

| electric relay | Omron, Japan |

| Inductive switch | SICK, Germany |

| Air cylinder | AirTAC,China Taiwan |

| Solenoid valve | AirTAC,China Taiwan |

| Stepper motor | JMK motion,CN |

| Air source processor | AirTAC,China Taiwan |

Ideal Applications for the HX-007 Semi-Automatic Ultrasonic Plastic Tube Sealing Machine

Widely used for food, Pharmaceutical, cosmetics, chemical and other plastic, PE, aluminum laminated tube filling and sealing.

Plastic and Composite Tube

- Sunscreen

- Aloe Vera Gel

- Eye Cream

Aluminum-Plastic Tube

- Hand Cream

- Silicone Grease

- Body Lotion Cream

Custom-Made Tube

- Facial Cleanser

- Makeup Remover

- Serum

Reviews

There are no reviews yet.