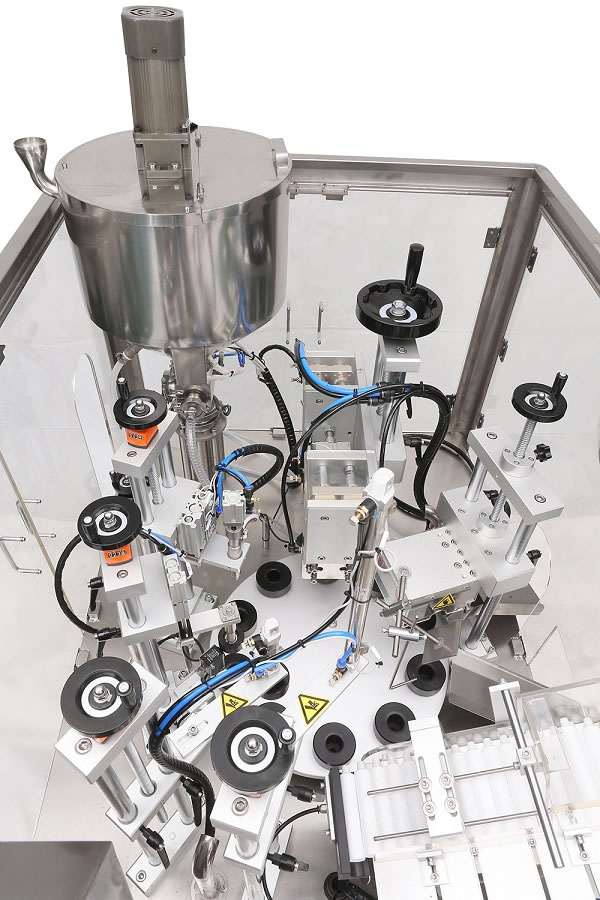

HX-009 Fully Automatic Ultrasonic Toothpaste Tube Filling And Sealing Machine

Consult now to get discount

- High quality

- Fast delivery

- After-sales guarantee

Meet the HX-009: Your Ultimate Solution for Toothpaste Tube Filling and Sealing

Advanced Features of the HX-009 Fully Automatic Ultrasonic Toothpaste Tube Filling And Sealing Machine

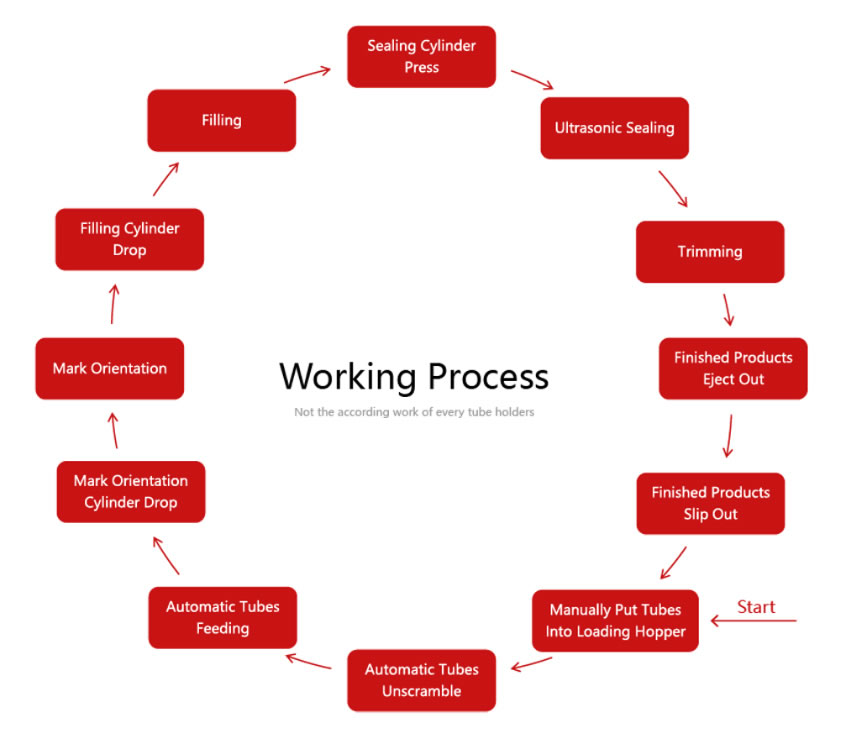

- Machine could automatically finish tube feeding, registration mark identifying, filling, sealing with coding, end trimming, tube out feeding, fully automatic, save labor cost and lower production cost.

- Machine is equipped with safety protection device and overload protection.

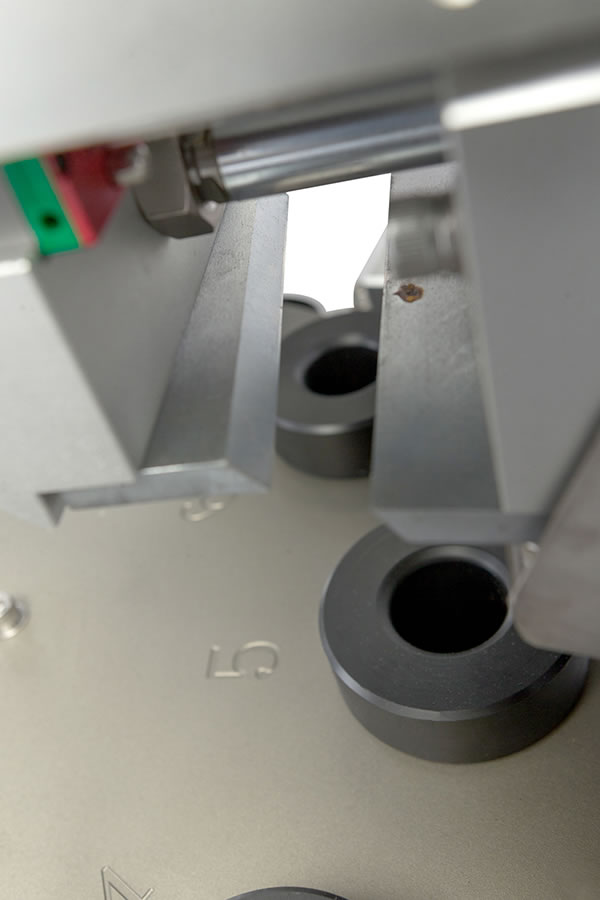

- Cam indexing system could position precisely for ten working stations.

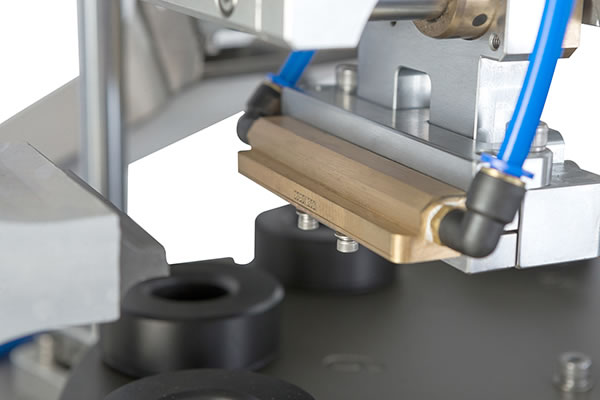

- Adopts ultrasonic sealing technology, no need warm up time, more stable and neat sealing, no distortion and low reject rate less than 1%.

- Independent R & D for digital ultrasonic automatic tracking electrical control box, no need manual adjust the frequency, with power auto compensation function, avoiding the reduction of power after long time use. Could freely adjust the power based on tube material and size, stable and minimum the fault rate, extend the life span than the normal electrical box.

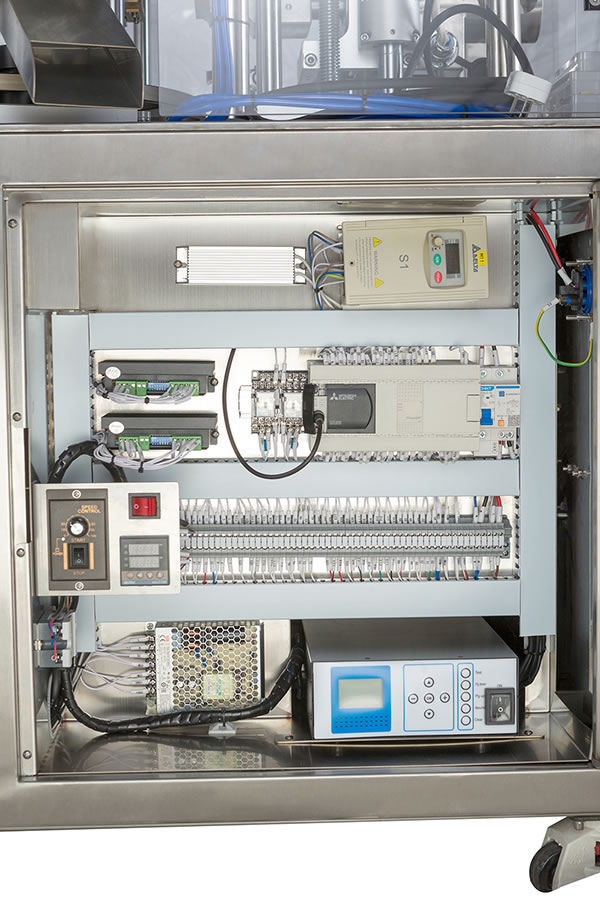

- PLC with touch screen control system with alarm system, could directly view the alarm information on the touch screen, could locate the problem and solve immediately.

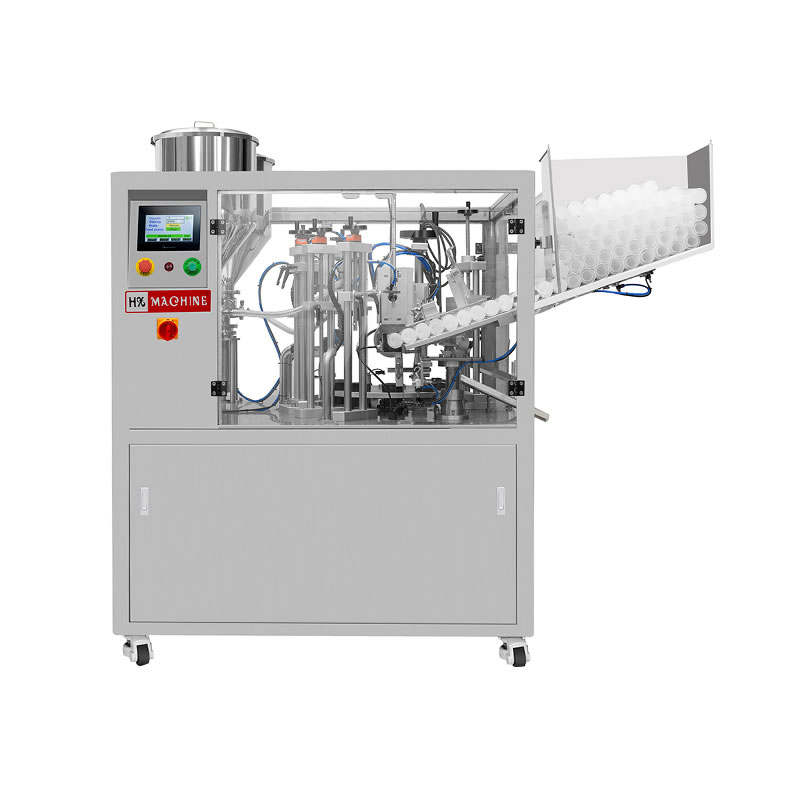

- Made of 304 stainless Steel, acid and alkali resistance, corrosion resistance.

- No tube, no fill, no tube, no seal function, reducing the machine and mould loss.

- Adopts Anti-dripping filling nozzle.

- Low power consumption as ultrasonic parts has high conversion rate of electrical energy to thermal energy.

Ideal Applications for the HX-009 Fully Automatic Ultrasonic Toothpaste Tube Filling And Sealing Machine

Widely used for food, Pharmaceutical, cosmetics, chemical and other plastic, PE, aluminum laminated tube filling and sealing.

Plastic and Composite Tube

- Sunscreen

- Aloe Vera Gel

- Eye Cream

Aluminum-Plastic Tube

- Hand Cream

- Silicone Grease

- Body Lotion Cream

Custom-Made Tube

- Facial Cleanser

- Makeup Remover

- Serum

Specification & Technical parameter

|

|

| |

| Model | HX-009S | HX-009 (The model you are browsing) | HX-005H |

| Auto/Semi-Auto | Fully automatic | Fully automatic | Fully automatic |

| Function | Filling and sealing | Filling and sealing | Filling and sealing |

| Safety Protection | Safety device equiped Overload protection | Overload protection | Safety device equiped Overload protection |

| Station | Ten stations (rotary table) | Ten stations (rotary table) | Servo motor driven chain type |

| Anti-Driping Filling | Anti-dripping Filling nozzle | Anti-dripping Filling nozzle | / |

| Tube Type | Dual-chamber tube | Single tube | Strip monodose vials tubes |

| Tube Material | Plastic tube ABL tube | Plastic tube ABL tube | PE Plastic PP Plastic |

| Color Mark System | Panasonic Color Mark Sensor | Panasonic Color Mark Sensor | / |

| Tube Outlet Detection | Discharge check alarm system | Discharge check alarm system | / |

| Fault Alram | Failure warning feature | Failure warning feature | Failure warning feature |

| Frequency | 20 kHz | 20 kHz | 20 kHz |

| Power | 2.6 KW | 2.6 KW | 2.6 KW |

| Power Supply | AC220V/110V | AC220V/110V | AC220V/110V |

| Filling System | Pneumatic piston pump | Pneumatic piston pump | 5 heads Valveless Ceramic Plunger Pump (liquid) 5 heads Rotary Valve Ceramic Plunger Pump (paste) |

| Filling Range | A. 10-120 ml B. 25-250 ml | A. 6-60 ml B. 10-120 ml C. 25-250 ml D. 50-500 ml | 0.3-10 ml Valveless Ceramic Plunger Pump 1-10 ml Rotary Valve Ceramic Plunger Pump |

| Filling Error | ≤±1% | ≤±1% | ≤±1% |

| Capacity | 8-13 pcs/min | 22-28 pcs/min | 15-20 monodose/min |

| Tube Diameter | 25-50 mm | 13-50 mm | 1-7 monodoses/length 140 mm |

| Tube Height | 50-210 mm | 50-250 mm | 50-120 mm |

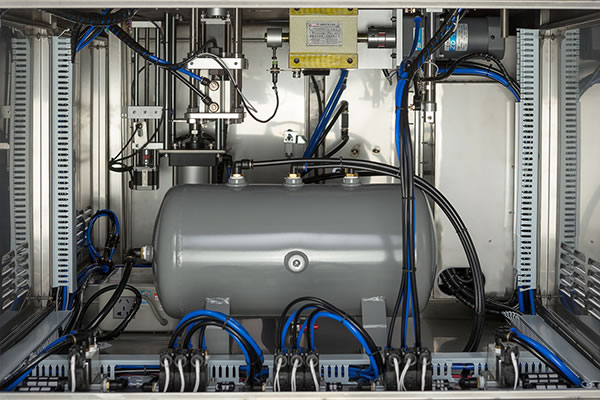

| Working Pressure | 0.6 MPa | 0.6 MPa | 0.4 MPa |

| Air Comsumption | 0.48m3/min | 0.38m3/min | 0.2m3/min |

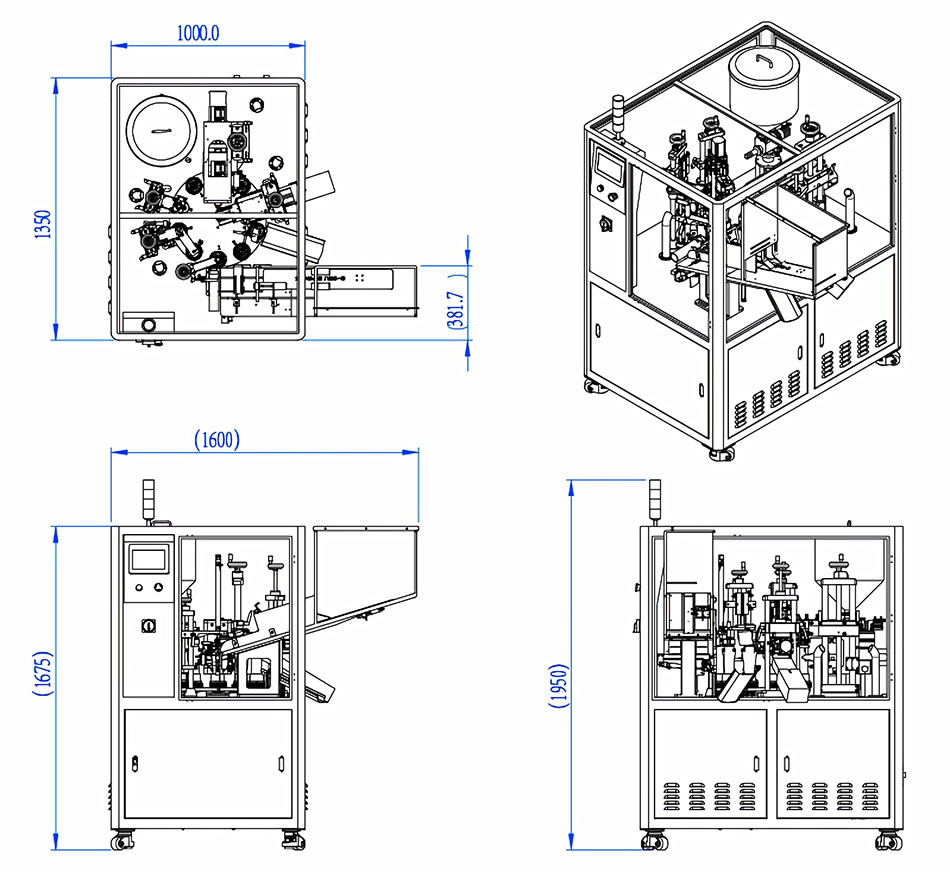

| Dimension (mm) | L1850*W1400*H1800 | L1590*W1400*H1650 | L1300*W1300*H1950 |

| N.W/G.W | 504 kgs | 424 kgs | 420 kgs |

| Option |

|

| Finish products conveyor |

Notice: If have additional purposes of filling, please contact us to determine the correct packaging substrate and structure.

| Main Part List | |

|---|---|

| Ultrasonic System | Automatic Frequency Tracing |

| Benchmarking Electric Eye | Panasonic, Japan |

| PLC | Mitsubishi, Japan |

| Electric Relay | Omron, Japan |

| Touch Panel | WEINVIEW,China Taiwan |

| Inductive Switch | SICK, Germany |

| Air Cylinder | AirTAC,China Taiwan |

| Solenoid Valve | AirTAC,China Taiwan |

| Motor | ZhongdaMotor CN |

| Partitioner | JOUDER,China Taiwan |

| Frequency Converter | DELTA,China Taiwan |

| Stepper Motor | Leadshine,CN |

Reviews

There are no reviews yet.