HX-009S Fully Automatic Ultrasonic Dual-Chamber Tube Filling Sealing Machine

Consult now to get discount

- High quality

- Fast delivery

- After-sales guarantee

Meet the HX-009S: Your Ultimate Solution for Dual-Chamber Tube Filling Sealing

Advanced Features of the HX-009S Fully Automatic Ultrasonic Dual-Chamber Tube Filling Sealing Machine

- Machine can automatically process dual chamber tube feeding, auto rotate to fill outer tube, registration mark identifying, filling inner tube, sealing, end trimming, tube out feeding. The machine is fully automatic and can save labor cost and lower production cost as well as provide possibility of creative two formular products.

- Machine is equipped with safety protection device and overload protection.

- Cam indexing system could position precisely for ten working stations.

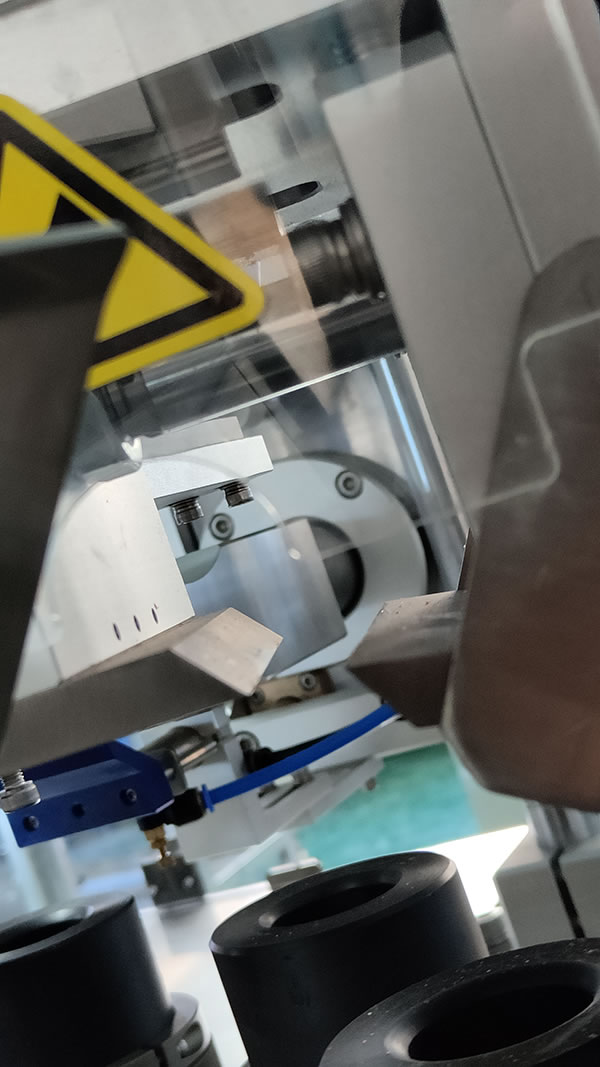

- Adopts ultrasonic sealing technology, no need warm up time, more stable and neat sealing, no distortion and low reject rate less than 1%.

- Independent R&D for digital ultrasonic automatic tracking electrical control box. No need manual adjust the frequency. With power auto compensation function, the machine can avoid the reduction of power after long time use. Could freely adjust the power based on tube material and size, stable and minimum the fault rate, extend the life span than the normal electrical box.

- PLC with touch screen control system with alarm system, could directly view the alarm information on the touch screen and locate, solve the problem immediately.

- Made of 304 stainless steel, acid and alkali resistance, corrosion resistance.

- No tube, no fill, no tube, no seal function, reducing the machine and mould wear.

- Adopts anti-dripping filling nozzle.

- Titanium alloy screw is used for the connection between the mold and the transducer of this machine.

- The machine is equipped with C440 stainless steel material cutter.

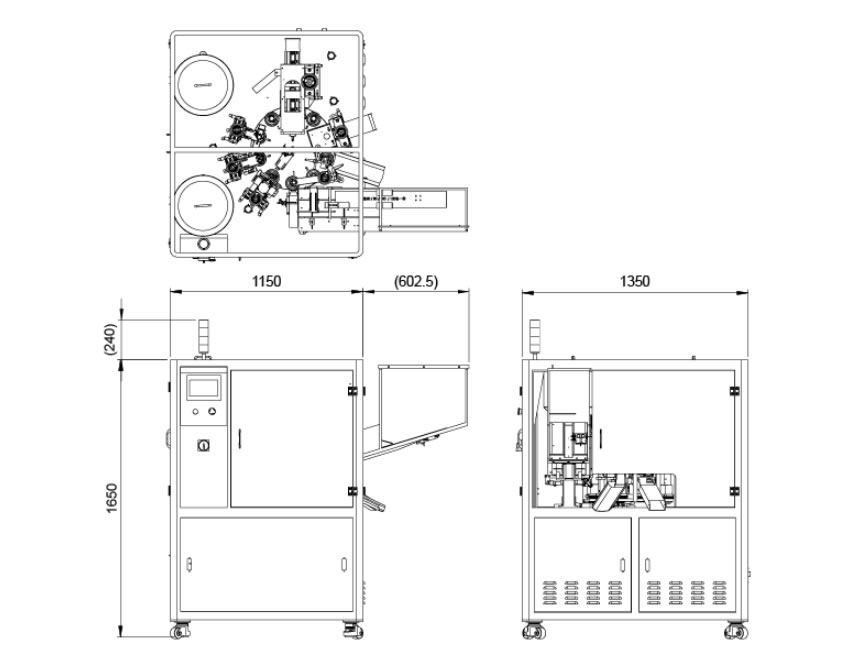

Specification & Technical parameter

| Machine Parameters | |

| Model | HX-009S |

| Frequency | 20kHz |

| Power | 2600W |

| Power supply | AC220V/110V |

| Filling Range | B.10-120ml C.25-250ml |

| Filling accuracy | ±1g |

| Capacity | 8-13pcs/min |

| Tube diameter | 25-50mm |

| Tube height | 100-210mm |

| Working pressure | 0.6 MPa |

| Size | L1850*W1400*H1800 |

| N.W/G.W | 504kgs |

| Main part list: | |

| Ultrasonic system | Automatic frequency tracing |

| Benchmarking electric eye | Panasonic, Japan |

| PLC | Mitsubishi, Japan |

| electric relay | Omron, Japan |

| Touch Panel | WEINVIEW, China Taiwan |

| Inductive switch | SICK, Germany |

| Air cylinder | AirTAC, China Taiwan |

| Solenoid valve | AirTAC, China Taiwan |

| Motor | Ding Hong CN |

| Partitioner | JOUDER, China Taiwan |

| Frequency converter | DELTA, China Taiwan |

| Stepper motor | Leadshine, CN |

Reviews

There are no reviews yet.